Level Probing Radar

foam layer

liquid level

foam layer

liquid level

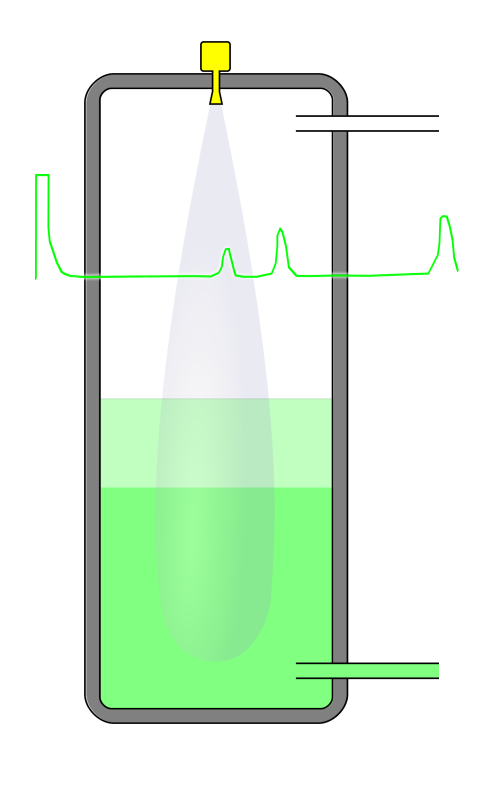

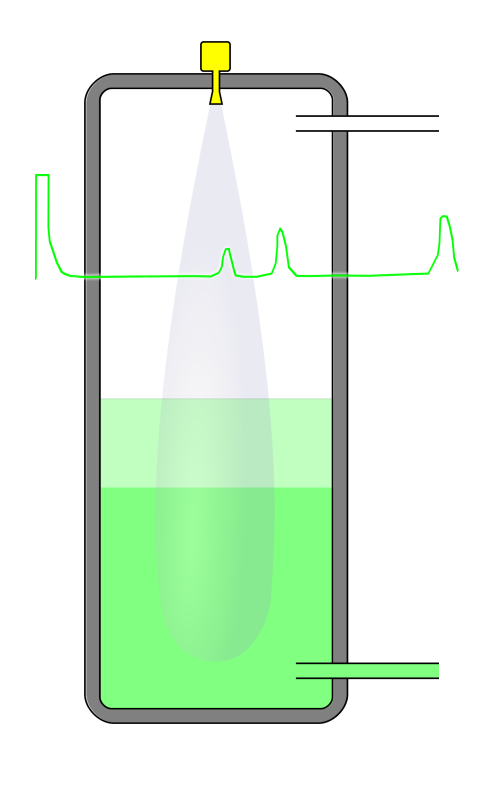

Figure 1: Non-contacting level probing radar

Level Probing Radar

Level Probing Radar (LPR) devices are short-range radar transceivers

widely used in industrial process instrumentation for contactless level measurement of various substances,

mostly liquids or granulates in tanks.

LPR equipment may operate in open-air environments or inside an enclosure (storage tank) containing the substance being measured.

The LPR transmits microwave energy from the top of the storage tank to the filling, which reflects a portion thereof.

The distance to the filling material surface is then determined by the runtime of the received from LPR echo signals.

By a known vessel geometry can be calculated the fill level using the runtime measurement.

LPRs are used in many industries concerned with process control to measure the level of various substances

(mostly liquids or granulates). LPRs are used for a wide range of applications such as process control,

custody transfer measurement (government legal measurements), water and other liquid monitoring,

spilling prevention and other industrial applications.

Two basic signal processing techniques are applied: Non-Contacting Radar and Guided Wave Radar.

The first is done by monitoring a microwave signal that is transmitted through free space and reflected back,

the second one can be executed as a “radar on a wire” technique, it uses the principles of time-domain reflectometry.

Non-Contacting Radar

A microwave signal launched into the tank is reflected back from the media surface.

The level is derived from the time or frequency difference between the sending and receiving of the signal.

- For liquid or solid tank levels with wide temperature and pressure requirements

- Top mounted; can be isolated by valves

- Unaffected by media density, viscosity, dirty coatings, and corrosiveness.

Guided Wave Radar

Measurement is based on the time difference between sending and receiving

a microwave pulse sent down a probe and reflected back to the media surface.

- For level and interface measurement of liquids or solids

- Suitable for wide temperature and pressure requirements

- Top mounted

- Unaffected by media density, viscosity, conductivity, turbulence, foam, and dust.

Figure 1: Non-contacting level probing radar

Level Probing Radar

Level Probing Radar (LPR) devices are short-range radar transceivers widely used in industrial process instrumentation for contactless level measurement of various substances, mostly liquids or granulates in tanks. LPR equipment may operate in open-air environments or inside an enclosure (storage tank) containing the substance being measured. The LPR transmits microwave energy from the top of the storage tank to the filling, which reflects a portion thereof. The distance to the filling material surface is then determined by the runtime of the received from LPR echo signals. By a known vessel geometry can be calculated the fill level using the runtime measurement.

LPRs are used in many industries concerned with process control to measure the level of various substances (mostly liquids or granulates). LPRs are used for a wide range of applications such as process control, custody transfer measurement (government legal measurements), water and other liquid monitoring, spilling prevention and other industrial applications.

Two basic signal processing techniques are applied: Non-Contacting Radar and Guided Wave Radar. The first is done by monitoring a microwave signal that is transmitted through free space and reflected back, the second one can be executed as a “radar on a wire” technique, it uses the principles of time-domain reflectometry.

Non-Contacting Radar

A microwave signal launched into the tank is reflected back from the media surface. The level is derived from the time or frequency difference between the sending and receiving of the signal.

- For liquid or solid tank levels with wide temperature and pressure requirements

- Top mounted; can be isolated by valves

- Unaffected by media density, viscosity, dirty coatings, and corrosiveness.

Guided Wave Radar

Measurement is based on the time difference between sending and receiving a microwave pulse sent down a probe and reflected back to the media surface.

- For level and interface measurement of liquids or solids

- Suitable for wide temperature and pressure requirements

- Top mounted

- Unaffected by media density, viscosity, conductivity, turbulence, foam, and dust.